At Outbuilders, we often get asked: Are pole barns cheaper to build than traditional structures? This question is crucial for anyone considering a new construction project, especially those looking to maximize their budget.

In this post, we’ll break down the costs associated with pole barns and traditional buildings, helping you make an informed decision for your next project.

What Are Pole Barns?

The Basics of Pole Barn Construction

Pole barn framing is a type of building framing that consists of a building supported by posts or poles that are buried into the ground. The fundamental principle of pole barn construction centers on large poles or posts embedded directly into the ground or set on concrete piers. These posts act as the primary support for the roof and walls, which eliminates the need for a traditional foundation. This method reduces construction time and costs significantly.

The poles, typically made of treated wood, can withstand ground contact and moisture. Roof trusses attach directly to these poles, creating a sturdy frame. Wall girts (horizontal supports between the poles) provide additional stability and serve as attachment points for siding materials.

Materials Used in Pole Barn Construction

The choice of materials plays a key role in the durability and cost-effectiveness of pole barns. Common materials include:

- Treated Wood Posts: These form the backbone of the structure.

- Metal Roofing: Often preferred for its longevity and low maintenance.

- Metal or Wood Siding: The choice depends on budget and aesthetic preferences.

- Trusses: Usually pre-fabricated for quicker installation.

A 2023 survey by the National Frame Building Association found that metal roofing is used in over 80% of new pole barn constructions due to its durability and cost-effectiveness.

How Pole Barns Differ from Traditional Structures

The main differences between pole barns and traditional structures lie in their construction method and foundation requirements. Traditional buildings typically require a full concrete foundation (which can account for up to 15% of the total construction cost, according to the National Association of Home Builders).

Pole barns, however, can be built on various surfaces, including gravel or compacted soil, with minimal site preparation. This flexibility reduces costs and allows for quicker construction times. On average, a pole barn can be erected in about half the time of a similarly sized traditional structure.

Another key difference is the interior space utilization. Pole barns offer large, open spaces without internal load-bearing walls, which provides greater flexibility in interior layout and usage. This makes them particularly suitable for agricultural storage, workshops, or even residential conversions.

It’s important to consider local building codes and climate conditions when deciding between a pole barn and a traditional structure. Each client’s specific needs and site conditions should be assessed to recommend the most suitable and cost-effective solution.

Now that we understand what pole barns are and how they differ from traditional structures, let’s examine the cost comparison between these two construction methods in more detail.

How Much Do Pole Barns Cost Compared to Traditional Buildings?

Initial Construction Costs

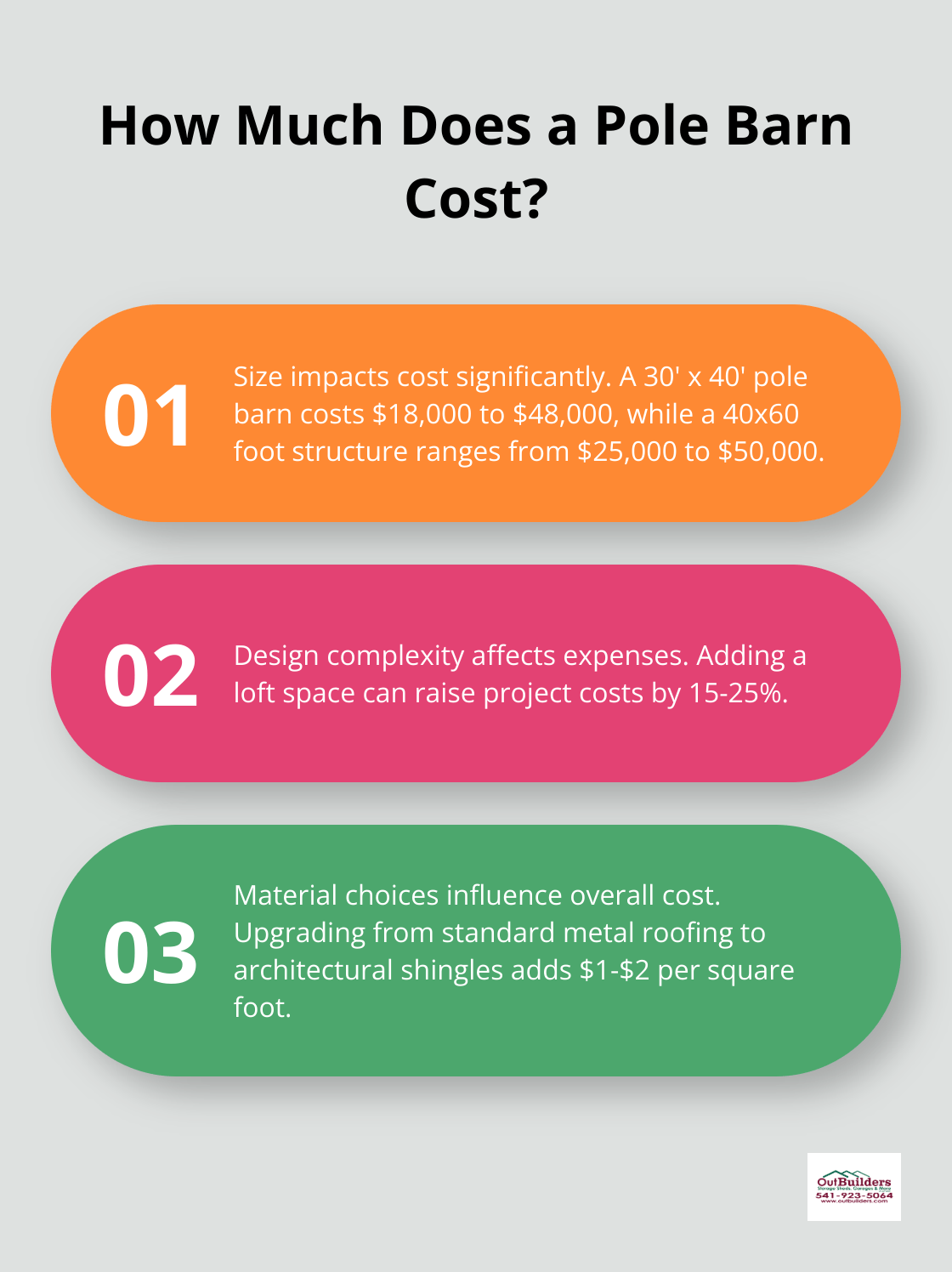

Pole barns offer significant cost savings compared to traditional structures. Costs can range from around $15 to $40 per square foot for a standard pole barn. This difference stems from the simplified foundation and framing process.

A 30×40 foot pole barn typically costs between $15,000 to $25,000, while a similar-sized traditional structure ranges from $30,000 to $50,000. (These figures may vary based on location, materials, and specific design requirements.)

Labor and Time Savings

Pole barn construction requires less labor and time, which translates to lower costs. Barns take no more than three weeks to build, on average and pending size. This efficiency results in labor costs that are 20-30% lower than those for traditional buildings.

Long-Term Expenses

While initial costs are lower, long-term expenses deserve consideration. Pole barns, when properly constructed and maintained, prove surprisingly durable. However, they may require more frequent maintenance than traditional structures.

Wood posts in contact with the ground can become susceptible to rot and insect damage over time. Many builders use pressure-treated lumber and metal brackets to elevate the wood above ground level, which significantly extends the structure’s lifespan.

Maintenance Costs

Maintenance costs for pole barns average about 1-2% of the building’s value annually, comparable to traditional structures. The simplicity of pole barn design often makes repairs easier and less expensive when needed.

Energy Efficiency Considerations

Traditional buildings typically have better insulation capabilities, which can lead to lower heating and cooling costs over time. However, modern pole barn construction techniques have improved significantly. With proper insulation, the energy efficiency gap narrows considerably.

The cost-effectiveness of pole barns makes them an attractive option for many projects, especially those requiring large, open spaces or flexible designs. However, the next chapter will explore additional factors that influence the overall cost of pole barn construction.

What Impacts Pole Barn Costs?

Size and Design Complexity

The size of a pole barn directly affects its cost. Larger structures require more materials and labor, which increases overall expenses. However, the cost per square foot often decreases as the size increases due to economies of scale.

Design complexity also significantly influences the price. Simple, rectangular designs are the most cost-effective. The addition of features like multiple stories, complex rooflines, or unconventional shapes can increase costs. The cost to build a pole barn can range from $20-$60 per square foot.

Local Regulations and Permits

Building codes and permit requirements vary widely by location and can substantially impact costs. Some areas have strict regulations for pole barns, especially if they’re intended for residential use. Permit fees can range from a few hundred to several thousand dollars (depending on the location and the project’s scope).

In Central Oregon, permit costs for a standard pole barn typically range from $500 to $2,000. However, these costs can increase if additional inspections or engineering reports are required. It’s important to check with the local building department early in the planning process to understand all requirements and associated costs.

Site Preparation and Foundation

Site conditions greatly affect preparation costs. A level site with good drainage will require minimal work, while sloped or rocky terrain can significantly increase expenses.

Foundation requirements also vary. While pole barns don’t require a continuous foundation, many areas require concrete footings for the poles. The depth of these footings depends on local frost lines and soil conditions. In some cases, a full concrete slab might be necessary (especially for residential or commercial use), which can add to the project cost.

Customization and Additional Features

Customization options can dramatically affect the final price of a pole barn. Basic models with minimal features are the most affordable, but adding elements like insulation, electricity, plumbing, or HVAC systems will increase costs.

For example, adding insulation to a pole barn can vary in cost. Cellulose insulation in the ceiling rafters can provide more R-value per foot, better sound barrier, and less cost than fiberglass. Installing electrical wiring and plumbing can also add to the overall cost, depending on the complexity of the systems.

Interior finishes also impact costs. A basic pole barn with exposed framing is the most economical option. However, if you plan to use the space as a workshop or living area, adding drywall, flooring, and other finishes can significantly increase the per-square-foot costs.

Final Thoughts

Pole barns are cheaper to build than traditional structures in many scenarios. Their cost-effectiveness comes from simplified construction methods, reduced material requirements, and shorter build times. This makes them an attractive option for those who seek economical building solutions, especially for agricultural, storage, or workshop purposes.

We recommend you assess your specific needs, local regulations, and long-term plans for the structure. Proper planning and design can maximize the benefits of pole barn construction while minimizing future expenses. You should balance initial cost savings with long-term value when you decide to build a pole barn.

At Outbuilders, we create high-quality, customized storage solutions, including pole barns, in Central Oregon. Our expert team can guide you through the process, ensuring your pole barn meets your specific requirements while adhering to local building codes. We deliver durable, personalized structures built on-site to your specifications (with our focus on exceptional craftsmanship and use of top-grade materials).

Recent Comments