Free stall dairy barn designs are critical for maximizing cow comfort and productivity. At Outbuilders, we understand the importance of getting these designs right.

This blog post will guide you through the key components of effective free stall barns, from stall dimensions to ventilation systems. We’ll also explore strategies for optimizing cow comfort and maintaining a clean, efficient facility.

What Makes an Effective Free Stall Dairy Barn?

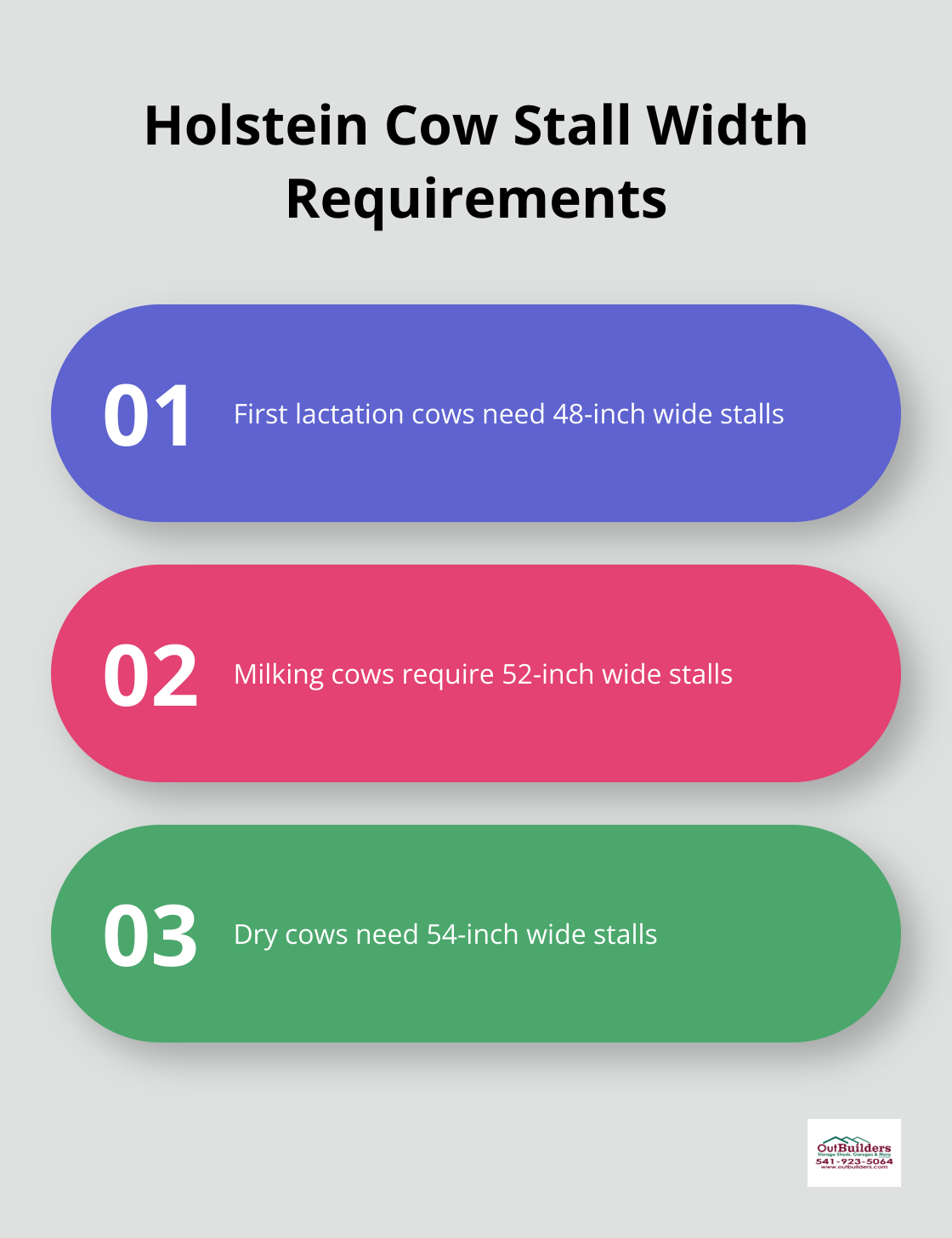

Stall Dimensions and Layout

The core of any free stall barn lies in its stalls. Holstein cows require specific stall widths: 48 inches for first lactation cows, 52 inches for milking cows, and 54 inches for dry cows. Stall length matters equally, with a minimum of 9 feet for head-to-wall configurations and 18 feet for head-to-head layouts. These dimensions allow cows to enter, lie down, and rise with ease.

A well-designed barn provides at least one stall per cow to eliminate competition. Overcrowding reduces lying time and increases stress, which can lead to decreased milk yield. Research indicates that cows should receive adequate rest for approximately 12 hours a day to optimize milk production.

Flooring and Drainage Systems

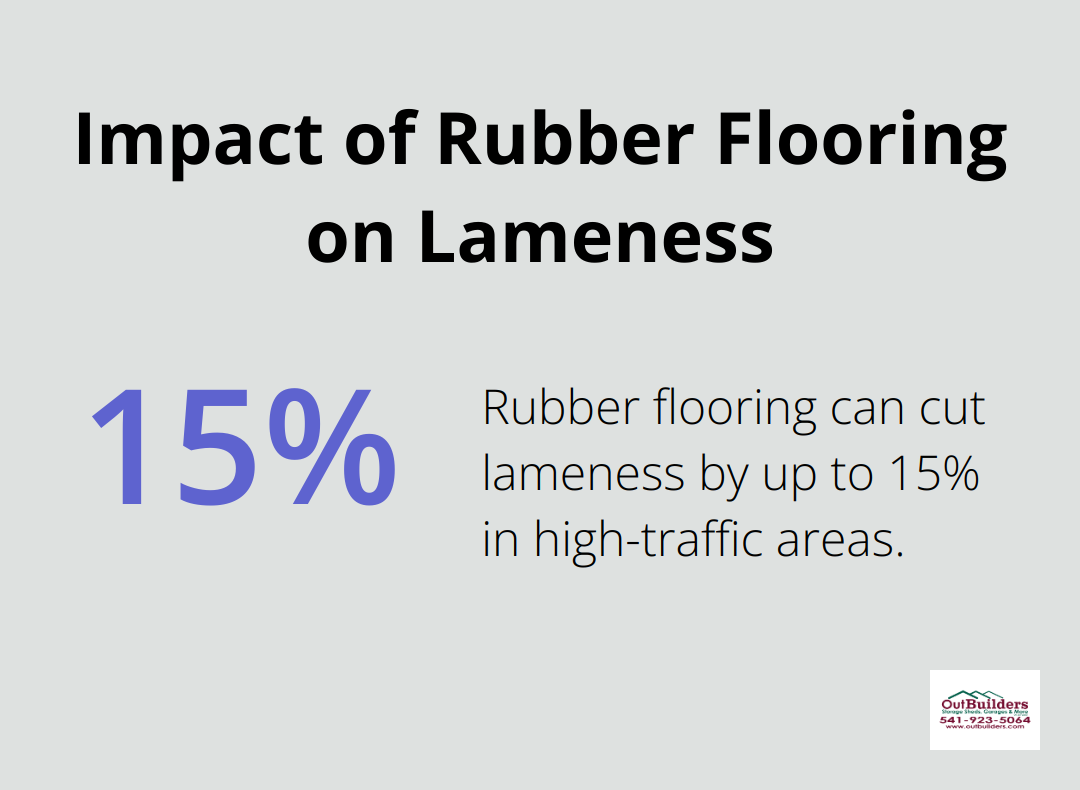

Proper flooring plays a vital role in cow health and comfort. While concrete remains common, it should have grooves or texture for traction. Rubber flooring in high-traffic areas can cut lameness by up to 15% (according to a Cornell University study).

Effective drainage is essential. The barn floor should slope 2-3% towards the center alley to facilitate waste removal. This design helps maintain dry and clean stalls, which reduces the risk of mastitis and other health issues.

Ventilation and Climate Control

Proper ventilation maintains air quality and regulates temperature. Natural ventilation through sidewall openings and ridge vents works well in many climates. For more controlled environments, mechanical ventilation systems offer an alternative.

The University of Minnesota suggests a minimum of 50 air changes per hour during hot weather to prevent heat stress. In colder regions, insulation and curtain sidewalls help maintain a comfortable environment while allowing proper air exchange.

Lighting and Electrical Systems

Lighting significantly impacts cow productivity. However, it’s important to note that some energy conservation measures can have negative impacts on a farm by reducing cow productivity or increasing labor or other costs.

LED lighting provides energy-efficient and consistent illumination. Install fixtures at least 8 feet above the floor to prevent damage and ensure even light distribution. Include red night lighting for monitoring without disrupting the cows’ circadian rhythms.

For electrical systems, safety takes priority. All wiring must have proper insulation and protection from moisture and physical damage. Regular inspections and maintenance of electrical systems prevent fire hazards and ensure continuous operation of critical equipment.

The next chapter will explore strategies to optimize cow comfort and productivity within these well-designed free stall barns.

How to Maximize Cow Comfort and Productivity in Free Stall Barns

Free stall barn design forms the foundation of a successful dairy operation, but the details within that structure can make or break cow comfort and productivity. This chapter explores key strategies to optimize your dairy barn’s performance.

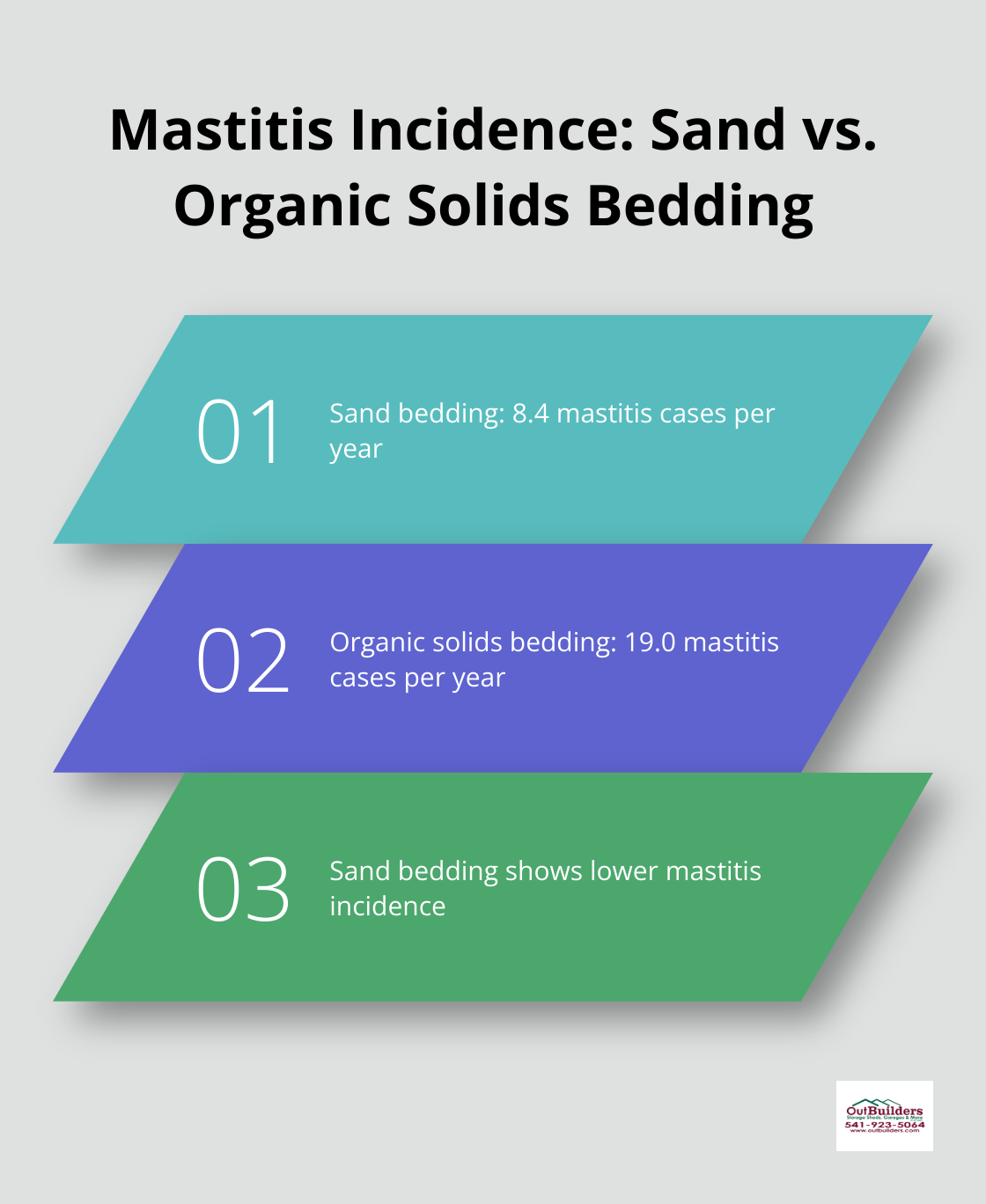

Choose the Right Bedding

Bedding selection impacts cow comfort and health significantly. Sand bedding often tops the list, providing excellent cushioning and udder health benefits. A study found that cows bedded with sand exhibited a lower incidence of mastitis compared to those bedded with organic solids (8.4 vs. 19.0 cases/yr).

Other options include deep-bedded compost or recycled manure solids. Whichever material you select, maintain consistency. Try to keep a bedding depth of at least 6 inches and replace or add fresh bedding regularly for a clean, dry surface.

Optimize Feed and Water Access

Easy access to feed and water drives high milk production. Provide at least 24 inches of bunk space per cow to minimize competition and stress during feeding times. Install waterers at a rate of one per 15-20 cows (with a minimum of two waterers per group) to prevent dominant cows from monopolizing access.

A feed push-up system ensures feed remains within reach. Automated systems can push up feed every two hours, encouraging more frequent eating and potentially increasing dry matter intake by up to 5%.

Design Efficient Traffic Flow

Efficient cow traffic flow reduces stress and maximizes time spent resting and eating. Design your barn layout with wide alleys (at least 12 feet for feed alleys and 10 feet for return alleys) to allow cows to pass each other comfortably.

Include multiple crossovers between rows of stalls – ideally one crossover for every 15-20 stalls. This setup allows cows to move freely between feeding and resting areas without creating bottlenecks or forcing long walks.

A well-designed traffic flow can have real impacts on production. A study investigated the effect of motivation to walk on cow gait and whether this effect differed between sound and lame cows.

Implement Stress Reduction Strategies

Stress reduction plays a key role in maintaining cow health and productivity. Consider these strategies:

- Install brushes for cow grooming.

- Use rubber flooring in high-traffic areas to reduce lameness.

- Maintain consistent routines for feeding and milking to minimize disruptions.

- Provide adequate space at the feed bunk and water troughs to reduce competition.

Monitor and Adjust

Regular monitoring and adjustment of your barn’s conditions ensure optimal performance. Use technology like activity monitors or rumination sensors to track cow behavior and health. Adjust ventilation, bedding, and feed management based on these insights and seasonal changes.

With these strategies in place, your free stall barn will not only house your cows but actively contribute to their comfort and productivity. The next chapter will explore how to maintain this optimized environment through effective cleaning and maintenance protocols.

How to Keep Your Free Stall Barn Clean and Functional

Daily Cleaning Routine

Establish a robust daily cleaning routine. Scrape manure from alleys at least three times daily, as research has shown this frequency can improve barn hygiene. Use automatic scrapers or skid steers with rubber blades to minimize floor damage. Some farms employ robotic scrapers that work continuously, which reduces labor costs and maintains consistently clean alleys.

Clean waterers daily to prevent algae growth and bacterial buildup. Clean water is crucial for maintaining milk production and health status in dairy cattle.

Add fresh bedding daily to maintain a 6-inch depth. Remove wet spots immediately to prevent mastitis.

Effective Manure Management

Implement a comprehensive manure management system. A well-designed system keeps your barn clean and provides valuable fertilizer for crops. Consider a flush system for larger operations; it cleans alleys effectively and moves manure to a storage facility or treatment system.

Smaller farms might find a scrape and haul system more cost-effective. Ensure proper storage capacity (six months of storage for regions with winter spreading restrictions).

Many farms now incorporate solid-liquid separation systems. These systems can reduce the volume of manure storage needed and create bedding material from the solids (potentially saving on bedding costs).

Pest Control Strategies

Implement an integrated pest management (IPM) program to control flies and other pests. Start with good sanitation practices – regular cleaning and proper manure management form the foundation of effective pest control.

Use fly parasites as a biological control method. These tiny, non-stinging wasps can reduce fly populations when used consistently. Combine this with targeted use of pesticides and fly traps for comprehensive control.

Don’t overlook rodent control. Place bait stations around the barn’s perimeter and maintain a clear zone around the building to discourage rodents from entering.

Preventive Maintenance Schedule

Develop a preventive maintenance schedule to catch small issues before they become big problems. Inspect the barn structure monthly for signs of wear or damage. Pay special attention to the roof, as leaks can quickly lead to wet bedding and increased mastitis risk.

Check ventilation systems weekly. Clean fans and adjust curtains as needed.

Inspect and maintain milking equipment daily. Replace rubber parts regularly and conduct a full system evaluation annually. This ensures efficient milking and helps maintain milk quality and prevent mastitis.

Final Thoughts

Free stall dairy barn designs have evolved to prioritize cow comfort and operational efficiency. These designs now incorporate precise stall dimensions, advanced ventilation systems, and strategic placement of feed and water access points. Regular monitoring and adjustment of these factors ensure the barn meets the changing needs of the herd.

Technology integration in free stall dairy barns will likely increase, with automated systems for feeding, cleaning, and health monitoring becoming standard features. Sustainability will play a larger role, focusing on energy-efficient designs and environmentally friendly waste management solutions. The dairy industry will continue to adapt, creating environments that promote health, productivity, and sustainability.

At Outbuilders, we understand the importance of well-designed structures for efficient operations. While we specialize in custom storage solutions, our commitment to quality craftsmanship applies to all our projects (including agricultural buildings). We encourage dairy farmers to stay informed about the latest advancements in barn design to create optimal environments for their herds.

Recent Comments